As technology continues to evolve, human interaction with robots will continue to increase. From a collaborating robot (cobot) creating your coffee in the morning at your local coffee shop to an autonomous mobile robot (AMR) roaming through a warehouse selecting packages. There are many aspects to which collaborating robots can be used in our daily lives.

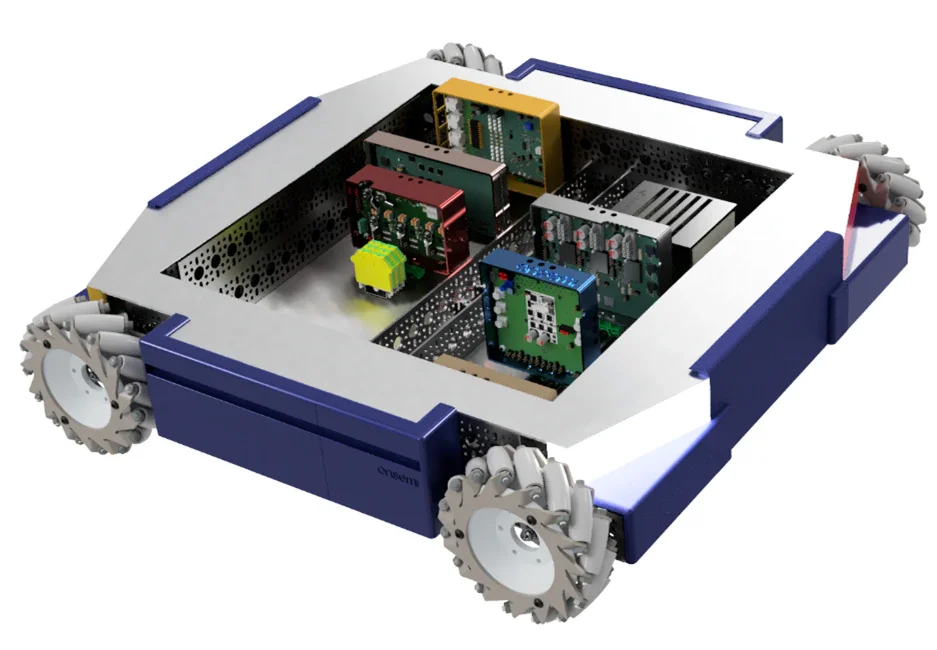

onsemi has developed an autonomous mobile robot demo that is developed from subsystem solutions, which is a comprehensive robotic design that uses innovative products from onsemi. This concept can be used to design various types of robots, cobots, power tools and autonomous guided vehicles by combining different sensing and intelligent power solutions from onsemi. In this blog, we interview Theo Kersjes,is part of Industrial Business Development and Solutions from onsemi to get more insight on what’s next with autonomous mobile robots.

Questions:

- We understand that onsemi has an autonomous mobile robot that’s made by a variety on subsystems from onsemi solutions. Can you briefly tell us about each subsystem that’s included?

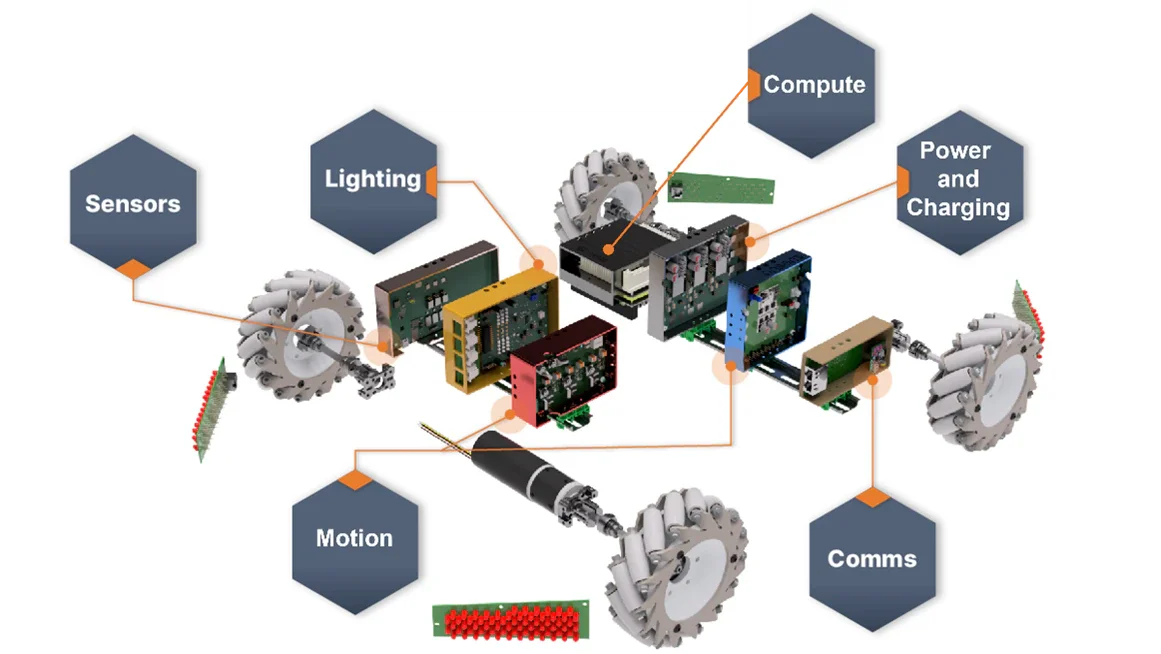

We make Evaluation Boards (EVB) and Development platforms around our products. These platforms are used in AMR sub-systems: Motion, Sensors, Power, Lighting and Communication. Together with a Control unit these form an autonomous mobile base that can navigate its environment and use collision avoidance when needed to safely reroute a path around an obstacle. To be able to upgrade and use our latest EVB and include some of our customer products, like cameras, the AMR uses DIN rails for mounting the EVBs and Ball head mounts ¼-20 for mounting sensors. Some of the highlighted onsemi products in each sub-system are:

Lighting

The Lighting sub-system communicates the AMRs state, status, and intentions for people around it. In smart retail inventory applications lighting can also be used to illuminate products in a dark store. The NCV7685 linear current driver and the NCL31000 is an intelligent LED driver that includes the capability for Visible Light Communication and Indoor Positioning EVB are used.

Motion

The Motion subsystem includes onsemi 3-phase gate drivers NCD83591 , Power Regulators NCP730 and latest Trench 10 MOSFET NVMFWS0DxN04XM solutions for BLDC motor drive.

Sensor

In the Sensor sub-system image sensors AR0234 and AR1335 are used as well as the NCS32100 angular inductive positioning sensors and ultrasonic sensor NCV75215.

Power

In the Power sub-system the FAN65008B is a PWM Buck regulator with integrated power MOSFETS is creating the power levels needed in the AMR from the 48V battery. The FAN65008B includes an array of protection circuits including OCP, TSD, OVP,UVP and SCP. The Power sub-system also includes Battery monitoring and ultra compact charging solution based on bridgeless totem pole NCP1681 and e-Fuse NIS3071 and current monitoring.

Communication

The Communication sub-system includes our NCN26010 a multi-drop IEEE 802.3cg compliant Ethernet 10Base-T1S Transceiver including MAC, a PLCA and Reconciliation Sublayer (RS). The 10Base-T1S is the backbone of the AMR linking all sub-systems. Lastly as the Control unit a NVIDIA® Jetson™ is used. This provides a good integration example of onsemi sub-systems in the Robot Operating System (ROS) implemented as a docker container.

2. Can you tell us about the onsemi products that have been added to the autonomous mobile robot and what functionalities they provide?

As indicated, we made the onsemi AMR using DIN rails to be able to add new products and features. For the upcoming year, one theme will be sensor fusion. In addition a continuing theme is safety byextending the Power subsystem with new onsemi electronic fuse products, e-Fuse NIS3071.

3. What challenge do you feel designers face when creating a robot? How do onsemi’s subsystem solutions allow for a simpler integration to meet these challenges?

This to me is one of the most important questions. For example, we work with companies that integrate onsemi image sensors and our LiDAR technology into their camera systems that enables the fusion of image sensing and depth perception all in a single system. How to better support them and understand and identify algorithms or functions that happen outside of our products and may move into our products in the future.

Same goes for the robot designers. Creating the onsemi AMR gave us insights on how the Nvidia Jetson running ROS (Robot Operating System) environment is used and what level of drivers are needed. In addition, it allows us to explore the Nvidia Omniverse™, Isaac Sim™ – Robotics Simulation and Synthetic Data. Simulation environments are key for safe AMR designs. The Simulation environments are used for training the mobile robots on syntectica data, obstecles that the mobile robot need to safely navigate. These simulation environments can also be used to navigate the most power efficient path, extending the time between battery charging, or use opportunity charging highlighting onsemi advantage with power efficient and intelligent sensing in the AMR sub-systems.

4. The robotic market is rapidly evolving, where do you see robotics in five years? What advances do you think will be made?

At this point the training wheels are off, or even better, the physical barriers have been removed for AMRs to move freely around people since they are safe and efficient. The environment is still controlled, a warehouse and or office environment with controlled lighting and level floors. AMRs will evolve to handle any environment as people do. In addition, true deployment flexibility is a key feature. This requires an interface to instruct or train the robot what to do without programming. Advances in NLP (Natural Language Processing), smart efficient hardware sensors, as well as power and control will be integrated into AMRs for general tasks. One moment the robot may operate a CNC machine and another moment the robot may package products. For example, in an agricultural setting one moment the AMR may weed, and another pick the ripe vegetables and then package these for shipment.

5. What is your favorite feature of the AMR? Do you have any fun stories to share about the design process?

Many things happened along the way of making the onsemi AMR, at one point the mecanum wheels were mounted wrong and random, resulting in the mobile robot having some very funny driving behavior in real life and correctly behaving in the simulation environment where the wheels where correctly mounted. Another time during the building process, we had the motor winding connections exposed and touching aluminum, resulting in back EMF (the affected wheel would not turn) and an engineer dismantling the wheel bearings, not understanding why the wheel would not turn. This became a fun EMF learning moment when new engineers would join the team. Many different engineers work on the sub-systems at onsemi. It was great to all to integrate this into one Autonomous Mobile Robot.

As the robotics industry continues to become more efficient and reliable in our everyday lives, onsemi will continue to develop technology that can be incorporated in AMRs. The sub-systems Motion, Sensors, Power, Lighting and Communication, are the building blocks for an Autonomous Mobile Robot. For more details regarding each sub-system please reach out to onsemi support.

Visit our Autonomous Mobile Robots solution page

Additional Resources:

___

About Theo Kersjes

With over twenty-five years international experience in product management, marketing and applications in the semiconductor industry, Theo is currently responsible for Industrial Business Development & Solutions in the Advanced Solutions Group at onsemi, managing a team of product definers and applications engineers for power and sensing solutions.

He started his career working on digital video and signal processing applications and moved from the Netherlands to the San Jose Bay area to work on broadband access, wireless connectivity, and digital power solutions. Joining a start-up, he developed unique 60Ghz wireless connectivity products and designed solutions for Industrial Marine ROVs. For onsemi Theo created the Autonomous Mobile Robot technology demonstrator from onsemi product development platforms including BLDC Motor Control, Image Sensors, LED Lighting drivers, Power Conversion, and connectivity solutions.